Productions of tailor-made moulds for concrete castings

Each mould we use is produced by us. We’ll produce it for you as well. One-time moulds for concrete are economic and serve only for few castings. If you want to make more pieces of the same concrete casting, we’ll advise you how to optimize costs for mould in the best way. We have experiences from small moulds for USD discs to large moulds for monolithic stairs.

For the production of mould, a positive model is necessary. Models tend to be complicated, so we need to use modern technologies, like 3D print or finishing at a 5-axis CNC machine. For this, a digital model in a *.3ds or *.stl format is necessary. Based on the drawings, we can prepare you this digital printout and prepare you a model. It’s enough to send us your plan or tell us your idea how the product should look like. According to these input parameters, we already know how much you are going to pay for the moulds. We’ll help you to optimize the price for mould according to an estimated number of castings.

The preparation of model is the first important step to start a successful project. We will handle the design in 3D programs (*.3ds, *.stl, *.skp, and many other). On a 5-axis CNC milling machine, we can create the model on the basis of data you sent from different materials like wood, aluminium, PVC, PP, silicone and other. Such model is the adjusted by us for the purpose of trouble-free moulding. The quality of model surface is important as well as an appropriate material chosen for the production of mould. The optimal proportion of price and repetitive use of mould forms the basis of successful business and we know how to do it.

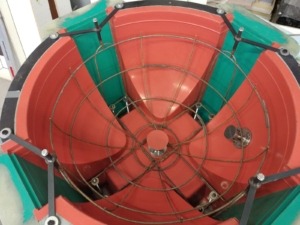

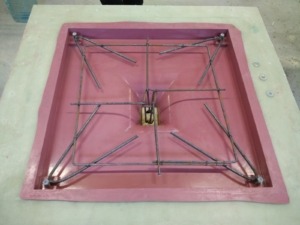

Shaping of already prepared model produced by us or supplied externally is not a problem. We always choose such technologies of mould preparation that the model can sustain for long, if possible. We are trying to prepare the mould from so many parts that the joints are not visible on casting and it’s easy to put out a high-quality casting of concrete from the mould. Most frequently, we use the combination of materials like silicone moulds with a fibreglass body. It’s an optimisation of mould price, thus making the concrete castings cheaper. We have experiences on this field for more than 6 years.

We analyse the needs of our partners and new customers. We will design you an optimal number of moulds for the required time concrete castings’ production. Each mould will produce one casting per 24 hours. By an appropriate choice of separator, we’ll adjust the surface of raw concrete to a subsequent surface finishing. Mass production of concrete castings is demanding due to the maturity time of castings. Our castings lay in a prepared “maturing” shelves where they receive the best care possible. Slow drying out of a concrete surface is very important for its quality. Mass production of castings is planned months in advance.

In Švec beton, we are pretty much aware of the efforts, time and tools such production of moulds for concrete takes. Our approach towards moulds is very careful even after the production end. Standardly, customers have moulds stored in our storage for couple of years. When they come back to production again, moulds are waiting preserved and prepared for use. We use special paints for the storage of respective concrete mould materials. When the production is finished, we increase the lifetime and prolong the period, for which such mould may be used. Storage and fixation of moulds is a paid service.